Best Ceramic Fibre Blanket In North Delhi

24/7 Call center: +91 83830 29491

ALFATHERM INSULATION

About us

Welcome to ALFATHERM INSULATION, a leading company specializing in high-quality ceramic insulation products. With our wide range of offerings, including Ceramic Rope, Ceramic Blanket, Ceramic Board and Blocks, Ceramic Cloth, Rope & yarn, Ceramic Bulk, Ceramic Fiber Paper, and Ceramic Module, we cater to various industries and applications. In this article, we will explore each of these products in detail, highlighting their features, benefits, and applications.

ALFATHERM INSULATION is a renowned provider of top-notch ceramic insulation solutions. Our company has established itself as a trusted name in the industry, offering a comprehensive range of high-performance products. We prioritize quality, innovation, and customer satisfaction, ensuring that our clients receive the best solutions for their insulation needs.

ALFATHERM INSULATION

CERAMIC INSULATION

Heat Insulation 0%

Sound Insulation0%

Water Resistance 0%

Fire resistance0%

OUR PRODUCTS

Ceramic Rope

Ceramic rope dealer Shed Insulation have ceramic rope which is a remarkable material that finds applications in various industries, thanks to its exceptional thermal properties, durability, and versatility. Composed of high-quality ceramic fibers, this specialized rope offers excellent resistance to extreme temperatures and is widely used for sealing, insulation, and reinforcement purposes. In this article, we will delve into the characteristics, applications, and advantages of ceramic rope, highlighting its significance in diverse industrial sectors.

Ceramic Blanket

Ceramic Fibre Blanket Dealer Alfatherm Insulation has the best ceramic blanket a versatile and highly efficient insulation material widely used in various industries for its excellent thermal properties. It is made from high-grade ceramic fibers, which are lightweight and capable of withstanding extremely high temperatures. This type of insulation is known for its superior heat resistance, low thermal conductivity, and exceptional insulation performance, making it an ideal solution for applications requiring thermal insulation at elevated temperatures.

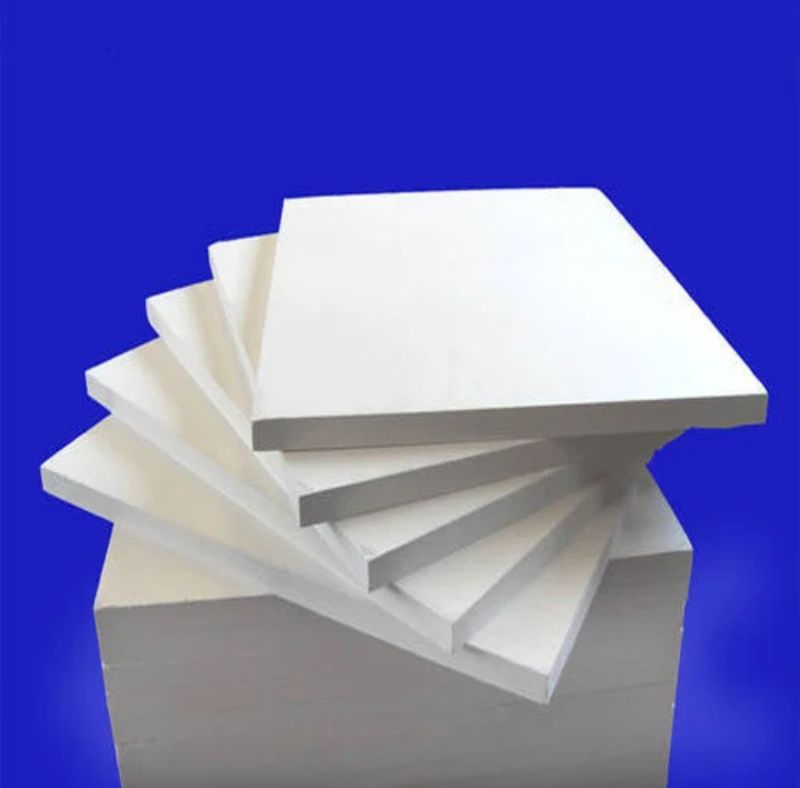

Ceramic Board and Blocks

Ceramic boards and blocks dealer versatile building materials that offer exceptional thermal, acoustic, and fire-resistant properties. They are widely used in various industries and applications, ranging from construction and insulation to aerospace and automotive sectors. In this article, we will explore the features, benefits, and applications of ceramic boards and blocks, highlighting their importance in modern engineering and design.

Ceramic Cloth, Rope & yarn

Ceramic cloth, rope, and yarn are innovative materials that offer exceptional heat and fire protection in various industries and applications. These specialized ceramic-based textiles are designed to withstand extreme temperatures, making them invaluable for thermal insulation, fireproofing, and other high-temperature environments. Let’s explore the characteristics and applications of ceramic cloth, rope, and yarn.

Ceramic Bulk

Ceramic bulk materials have been utilized for centuries due to their exceptional properties and wide-ranging applications. Composed of inorganic compounds, ceramics offer a unique combination of strength, hardness, thermal stability, and chemical resistance. These qualities make ceramic bulk an ideal choice for various industries, including aerospace, automotive, electronics, healthcare, and energy.

Ceramic Fiber Paper

Ceramic fiber paper is a lightweight, flexible, and high-temperature insulation material that has gained popularity across various industries. It is made from ceramic fibers, typically alumina-silica or pure alumina, processed into a thin paper-like form. This unique material offers exceptional thermal insulation, excellent electrical insulation properties, and other desirable characteristics, making it a versatile solution for a wide range of applications.

Ceramic Module

A ceramic module is an electronic component constructed using ceramic materials. These modules are designed to encapsulate or house various electronic circuits and components, providing protection and enhancing performance. Ceramic materials such as aluminum oxide (Al2O3) or aluminum nitride (AlN) are commonly used due to their exceptional thermal conductivity, electrical insulation properties, and mechanical strength.

Does ceramic insulate heat?

Yes, ceramic is known for its ability to insulate heat. It is a non-metallic, inorganic material that has excellent thermal insulation properties. Ceramic materials have a low thermal conductivity, which means they are not good conductors of heat. This property allows ceramics to prevent the transfer of heat from one side to another, making them effective as insulators.

Ceramic materials are often used in applications where heat insulation is required, such as in the construction of kilns, furnaces, and ovens.

They are also commonly used as insulating tiles on the exterior of spacecraft to protect against high temperatures during re-entry into the Earth’s atmosphere.

In addition to their thermal insulation properties, ceramics also possess other desirable characteristics, including high-temperature resistance, chemical resistance, and electrical insulation. These qualities make ceramics a versatile material for various industrial and technological applications.

Is ceramic insulator or conductor

Ceramic materials can exhibit a range of electrical properties, including both insulating and conducting behavior. The electrical behavior of ceramics depends on various factors, such as their composition, structure, and processing.

Certain ceramic materials, such as alumina (aluminum oxide) and porcelain, are commonly used as insulators due to their high electrical resistivity. These ceramics have a low conductivity and can effectively prevent the flow of electric current, making them suitable for applications where electrical insulation is required.

`

On the other hand, there are also ceramic materials that exhibit electrical conductivity. For example, certain types of ceramics called “electroceramics” can conduct electricity under specific conditions. These electroceramic materials, like piezoelectric ceramics and ferroelectric ceramics, possess unique electrical properties that make them useful for applications like sensors, actuators, and electronic components.

Therefore, it is essential to consider the specific type of ceramic and its intended application when determining whether it acts as an insulator or a conductor.

There are several types of ceramic insulation used for various applications. Here are some common types:

Ceramic Fiber Insulation: This type of insulation is made from high-temperature ceramic fibers, typically alumina-silica based. It offers excellent thermal insulation properties and is widely used in high-temperature applications such as furnaces, kilns, and industrial processes.

Ceramic Blanket: Ceramic blankets are lightweight and flexible insulation materials made from ceramic fibers.

They are often used for thermal insulation in industrial equipment, boilers, pipes, and ductwork. Ceramic blankets provide good heat resistance and thermal stability.

Ceramic Foam Insulation: Ceramic foam insulation consists of a porous structure made from ceramic materials. It offers both thermal insulation and sound absorption properties. Ceramic foam is used in various applications such as furnaces, engines, and thermal barriers.

Ceramic Insulating Bricks: These bricks are made from insulating ceramic materials with low thermal conductivity. They are used to construct insulating walls, linings, and barriers in high-temperature environments such as kilns, ovens, and fireplaces.

Ceramic Insulating Coatings: Ceramic coatings are thin layers of ceramic materials applied to surfaces for thermal insulation purposes. They provide heat resistance, thermal barrier properties, and can be used on metals, concrete, and other materials.

Ceramic Insulating Paints: These paints contain ceramic particles or additives that provide insulation properties when applied to surfaces. They are often used for thermal insulation of walls, roofs, and other structures.

Ceramic Insulating Beads: Ceramic beads or spheres made from insulating ceramic materials are used as fillers or additives in insulation materials. They enhance thermal insulation properties and are commonly used in lightweight concrete, insulation panels, and coatings.

These are just a few examples of ceramic insulation types. The specific type of ceramic insulation chosen depends on factors such as the desired insulation performance, temperature requirements, application method, and budget.

Ceramic insulation offers several benefits that make it a popular choice for various applications. Here are some of the key advantages of ceramic insulation:

High Temperature Resistance: Ceramic insulation exhibits excellent resistance to high temperatures, making it suitable for insulation in environments with extreme heat. It can withstand temperatures well above 1000 degrees Celsius (1832 degrees Fahrenheit) without deforming or degrading.

Thermal Insulation: Ceramic materials have low thermal conductivity, meaning they are effective at preventing heat transfer. By insulating with ceramics, you can reduce heat loss or gain, improving energy efficiency and maintaining comfortable temperatures in buildings or industrial processes.

Fire Resistance: Ceramic insulation is highly fire-resistant, as it does not burn or release toxic gases when exposed to flames. It helps in containing fires and preventing their spread, enhancing safety in both residential and industrial settings.

Chemical Resistance: Ceramics are known for their resistance to various chemicals, acids, and alkalis. This property makes ceramic insulation suitable for applications in industries dealing with corrosive substances, such as chemical processing, petrochemicals, and metal refining.

Electrical Insulation: Ceramics possess excellent electrical insulation properties, making them ideal for electrical and electronic applications. They can withstand high voltages and provide insulation in devices and systems, ensuring safety and preventing electrical hazards.

Lightweight and Durable: Ceramic insulation is lightweight compared to many other insulation materials. This characteristic makes it easier to handle and install. Additionally, ceramics are known for their durability, maintaining their insulating properties over long periods without significant degradation.

Sound Insulation: Ceramic insulation can help reduce sound transmission, providing acoustic insulation benefits. It can be used to create sound barriers or to enhance soundproofing in buildings, vehicles, or industrial settings where noise control is necessary.

Environmental Friendliness: Ceramics are typically made from natural materials like clay and silica, which are abundant and readily available. They are also non-toxic and do not release harmful substances into the environment. Ceramic insulation is often considered an environmentally friendly choice compared to synthetic insulation materials.

These benefits make ceramic insulation a versatile option for various applications, including residential and commercial buildings, industrial processes, aerospace, automotive, and more.

Frequently Asked Questions

Ceramic insulation is a type of thermal insulation material made from ceramic fibers or particles. It is designed to reduce heat transfer and provide excellent thermal insulation properties in various applications.

Ceramic insulation works by trapping air within its porous structure, creating a barrier that limits heat conduction. The high temperature resistance of ceramics allows them to withstand extreme temperatures while providing insulation.

Excellent thermal insulation properties:

- Ceramic insulation effectively reduces heat transfer and maintains stable temperatures.

- High-temperature resistance: It can withstand extreme temperatures, making it suitable for applications with high heat levels.

- Fire resistance: Ceramic insulation is non-combustible and can resist fire.

- Chemical resistance: It is resistant to most chemicals and corrosive substances.

- Lightweight: Ceramic insulation is relatively lightweight, making it easier to handle and install.

- Low thermal conductivity: It has low thermal conductivity, meaning it minimizes heat loss or gain.

- Longevity: Ceramic insulation is durable and can have a long lifespan.

Ceramic insulation is commonly used in various applications, including:

- Furnaces and kilns: It is used to insulate the walls, floors, and roofs of high-temperature industrial furnaces and kilns.

- Foundries: Ceramic insulation is used to line ladles, crucibles, and molds in foundries.

- Power generation: It is utilized in power plants to insulate boilers, pipes, and steam turbines.

- Automotive industry: Ceramic insulation is employed in exhaust systems, catalytic converters, and engine compartments.

- Aerospace industry: It is used in spacecraft, rockets, and jet engines to provide thermal protection.

- Home insulation: Ceramic insulation can be used in homes for attic insulation, wall insulation, and insulating fireplaces.

Ceramic insulation is generally considered safe to use. It is non-combustible and has a high melting point, reducing the risk of fire. However, it is essential to follow safety guidelines during installation, wear appropriate protective gear, and handle the insulation with care to avoid potential skin or respiratory irritation from the fibers.

Yes, some forms of ceramic insulation can be recycled. However, the recyclability may vary depending on the specific composition and type of ceramic insulation. It is recommended to check with recycling facilities or manufacturers for proper recycling methods and guidelines.

The cost of ceramic insulation varies depending on factors such as the type, thickness, and quantity required. It is best to consult with insulation suppliers or contractors to get accurate pricing information based on your specific needs.

Ceramic insulation offers advantages over other types of insulation in terms of high-temperature resistance, fire resistance, and chemical resistance. However, the choice of insulation material depends on the specific requirements of the application, such as temperature range, environmental conditions, and budget.

You can easily purchase ceramic material from by click:

Ceramic Fibre Blanket Dealer

Ceramic Board Dealer in delhi

Ceramic Board Supplier in delhi

Ceramic Fibre Blanket Price In Delhi

Ceramic Fibre Blanket In South Delhi

Best Ceramic Fibre Blanket In North Delhi

Best Ceramic Fibre Blanket In North Delhi

Ceramic Fibre Blanket In Ajmeri Gate Delhi